Thermoelectric.

Thermodielectric is a specific type of finely porous magnesium aluminium silicate, designed by Savar in the '80s. It is used in a wide range of applications, thanks to its unique properties.

Due to its extreme versatility, this innovative material is widely used in the power, heat insulation and refractory sectors. Its main properties include good electrical insulation, the capacity to operate at temperatures up to around 1250°C and remarkable resistance to thermal shocks.

It is commonly used to hold electrothermal elements in place, such as electrical resistors and thermocouples, and it is part of the extensive family of ceramics. The production process involves the painstaking selection of the finest raw materials to ensure optimum performance at high temperatures.

Properties of thermodielectric ceramics.

• Good mechanical resistance

• Good electrical resistance

• Good resistance to thermal shocks

• Good electrical resistance

• Good resistance to thermal shocks

Which products can we manufacture?

Savar thermodielectric ceramics are used in the manufacture of numerous products:

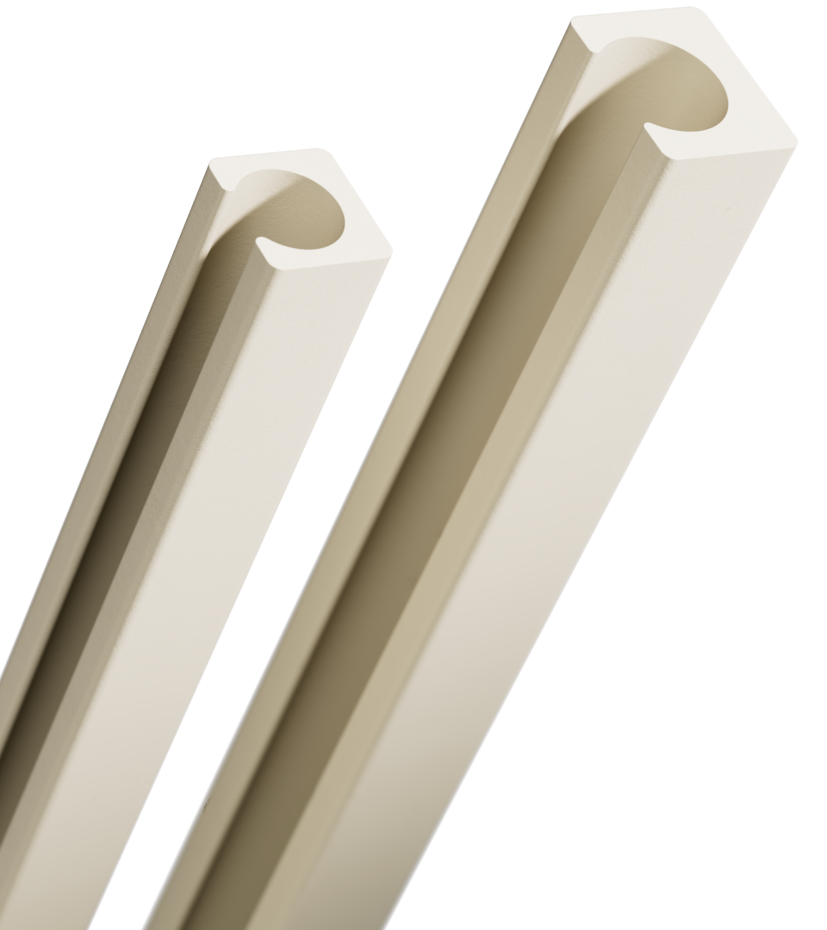

• Insulators for thermocouples

• Supports/holders for electrical resistors

• Bushings for electrical insulation

• Components for electrothermal equipment

• Protective coverings for industrial furnaces

• Instruments and accessories for electrical engineering

• Stoppers and tubes for terminal outlets in industrial electric furnaces

• Supports/holders for electrical resistors

• Bushings for electrical insulation

• Components for electrothermal equipment

• Protective coverings for industrial furnaces

• Instruments and accessories for electrical engineering

• Stoppers and tubes for terminal outlets in industrial electric furnaces

Sectors of use.

Dielectric ceramics are widely used in electrical and electronic engineering, in holders for resistors and thermocouples and in other insulating components. They also have numerous applications in the field of thermal insulation: thanks to their capacity to operate at high temperatures and to resist thermal shocks, they are ideal for applications that require effective heat insulation. In addition, they are utilised for the manufacture of coverings and components that must be able to resist high temperatures and aggressive environments.

Did you know...?

Thermodielectric products are made using specially selected, highest-quality compounds, and do not contain conducting components. It is important to note that, as in every insulating/isolating material, the dielectric properties tend to diminish as the temperature increases; at temperatures of around 1000-1100°C, stray currents can influence any differential protections. To limit this phenomenon, it is essential to use low voltages at all times.

If you are interested in our thermodielectric products or you would like to receive more information, please don't hesitate to get in touch. Our team is at your disposal to find the solution that best fits your needs.

Want a custom material?

Let's make it together.

Let's make it together.

Custom materials designed and produced in response to your ideas.

Our technicians analyse every technical detail with a view to meeting your requirements fully, developing specific formulations that satisfy the various technical and performance requirements you may have.

• Refractory products based on silicon carbide, zirconium oxide or fused silica

• Advanced ceramics, oxide and non-oxide

• Advanced ceramics, oxide and non-oxide

• High-porosity ceramics

• Super-refractory products with high alumina content