Alumina, more commonly known as aluminium oxide (Al2O3), is one of the most widely used of all the state-of-the-art ceramic materials. It is renowned equally for its high level of thermal insulation and for its low level of electrical conductivity. It is also highly resistant to acids, and is available in various polymorphous forms.

Its properties vary depending on the specific polymorphous form, making it extremely versatile. It is the preferred material out of all advanced ceramics, and is notable for the multiple uses to which it can be put and for its reliability in critical applications. Savar manufactures alumina with levels of Al2O3 that vary from 85% to 99%, all of which are exceptionally stable even at high temperatures and can, therefore, be used in a mutitude of different sectors. For example, porous alumina with up to 94% Al2O3 is used primarily in the Oil & Gas sector, as ferrules for tube sheets, whereas sintered alumina with Al2O3 levels of between 96% and 99% is utilised in the electrical and mechanical engineering sectors, and in the textile industry.

• High thermal conductivity and capacity for heat dispersal

• Resistant to mechanical stress and wear

• Levels of purity that vary from 85% to 99%, adaptable to various applications

• High level of chemical resistance to strong acids and bases

• Maintains its properties even at high temperatures

• Components for electronics and integrated circuits

• Components for industrial furnaces: tubes for high temperatures

• Wear-resistant precision mechanical components

• Textile and non-textile thread guides

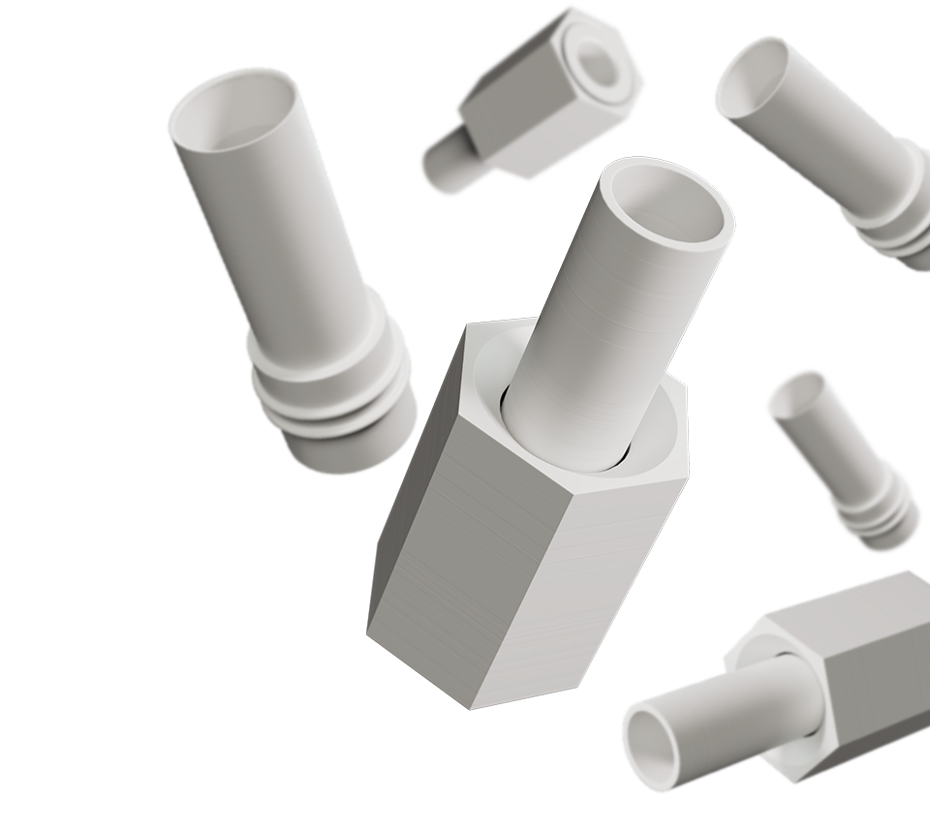

• Ferrules for the petrochemical sector

• Superior resistance to thermal shocks: ideal for variable temperature conditions.

• Precise dimensional tolerances: Savar's ferrules are pre-engineered and formed with tolerances of +/- 0.5% for perfect one-site adapability.

• High reliability: the generous curvature under the head of the ferrule minimises the concentration of stress.

• Heat-management system: protects the tube sheet from excessive heat, enhancing insulation and reducing the space and refractory material required when compared to traditional solutions.

• Ease of installation and maintenance: Savar's ferrules can be rapidly removed for periodic inspections and maintenance, with the option to reuse some or all of the ferrules, thus reducing the cost.

• Reduction of pressure drops: available with various tapered entry and exit profiles, helping to reduce the refractory mass in the furnace while also minimising pressure drops, with respect to installations that use refractory castables.

• Greater operating efficiency: enabling higher process throughput and lower energy costs, delivering higher perfomance and lower costs over time within heat cycles.

Let's make it together.

• Advanced ceramics, oxide and non-oxide