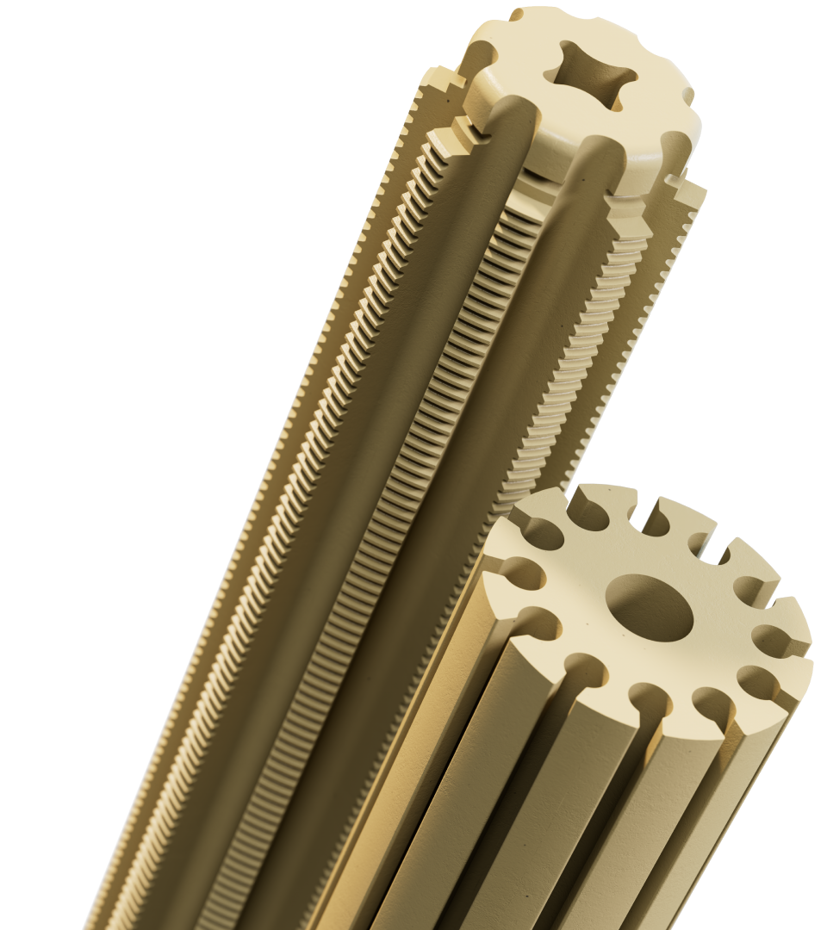

Cordierite.

Cordierite is a type of magnesium aluminium silicate, renowned for its exceptional properties of resistance to thermal shocks.

This ceramic material has low conductivity and a low co-efficient of thermal expansion, making it ideal for applications that involve rapid changes of temperature. Available in porous and dense versions, cordierite is versatile and offers great value-for-money.

Cordierite ceramics are used in numerous sectors thanks to this material's unique properties. Porous cordierite C520 is particularly highly esteemed for its superior properties of resistance to thermal shocks, making it ideal for heating applications. Dense cordierite C410, in contrast, is often used in the electrotechnical sector for the production of moulds of various types, thanks to its excellent dielectric rigidity and mechanical resistance.

Properties of cordierite.

• Excellent resistance to thermal shocks

• Low conductivity and thermal expansion

• Excellent mechanical resistance

• Versatility of use in technical components and heating applications

• Resistent to high temperatures: can be used up to around 1200°C

• Low conductivity and thermal expansion

• Excellent mechanical resistance

• Versatility of use in technical components and heating applications

• Resistent to high temperatures: can be used up to around 1200°C

Which products can we manufacture?

Savar's cordierite is used in the manufacture of numerous different products:

• Support/holders for heat conductors

• Protection against sparks

• Components for cartridge heaters

• Power resistors and electrical braking resistors

• Rheostats

• Honeycomb cells for heat exchangers

• Protection against sparks

• Components for cartridge heaters

• Power resistors and electrical braking resistors

• Rheostats

• Honeycomb cells for heat exchangers

Sectors of use.

In the electrotechnical sector, cordierite is used for the manufacture of insultating components and technical moulds, thanks to its excellent dielectric and mechanical properties. In gas engineering, cordierite is utilised for protection against sparks and in other safety components. For electrical heating systems, cordierite is an ideal support surface for heat conductors and cartridge heaters. In addition, in industrial furnaces, cordierite is used as a structural ceramic due to its excellent thermal characteristics, which enable it to operate at high temperatures. Dense cordierite C410 is used widely in the railway and transports sectors as a supports and holders for breaking resistors and power resistors.

Did you know...?

Cordierite, in both its porous and non-porous versions, has extraordinary properties that make it unique in various fields of application. This material is renowned for its low thermal conductivy, low expansion coefficient and low levels of resistance to heat and dielectric loss, as well as for its capacity to resist corrosion, above all in cast metal products. Moreover, thanks to its limited heat expansion, it is ideal for applications that require strict tolerances.

Porous cordierite, in contrast, has a lower level of mechanical resistance with respect to the non-porous version, but offers unique advantages thanks to its porosity. This characteristic enables it to absorb thermal impacts more effectively, making is particularly useful in situations of high thermal stress.

Porous cordierite, in contrast, has a lower level of mechanical resistance with respect to the non-porous version, but offers unique advantages thanks to its porosity. This characteristic enables it to absorb thermal impacts more effectively, making is particularly useful in situations of high thermal stress.

If you are interested in our cordierite products or you would like more information about them, please don't hesitate to get in touch. Our team is at your disposal to find the most appropriate solution to meet your needs.

Want a custom material?

Let's make it together.

Let's make it together.

Custom materials designed and produced in response to your ideas.

Our technicians analyse every technical detail with a view to meeting your requirements fully, developing specific formulations that satisfy the various technical and performance requirements you may have.

• Refractory products based on silicon carbide, zirconium oxide or fused silica

• Advanced ceramics, oxide and non-oxide

• Advanced ceramics, oxide and non-oxide

• High-porosity ceramics

• Super-refractory products with high alumina content